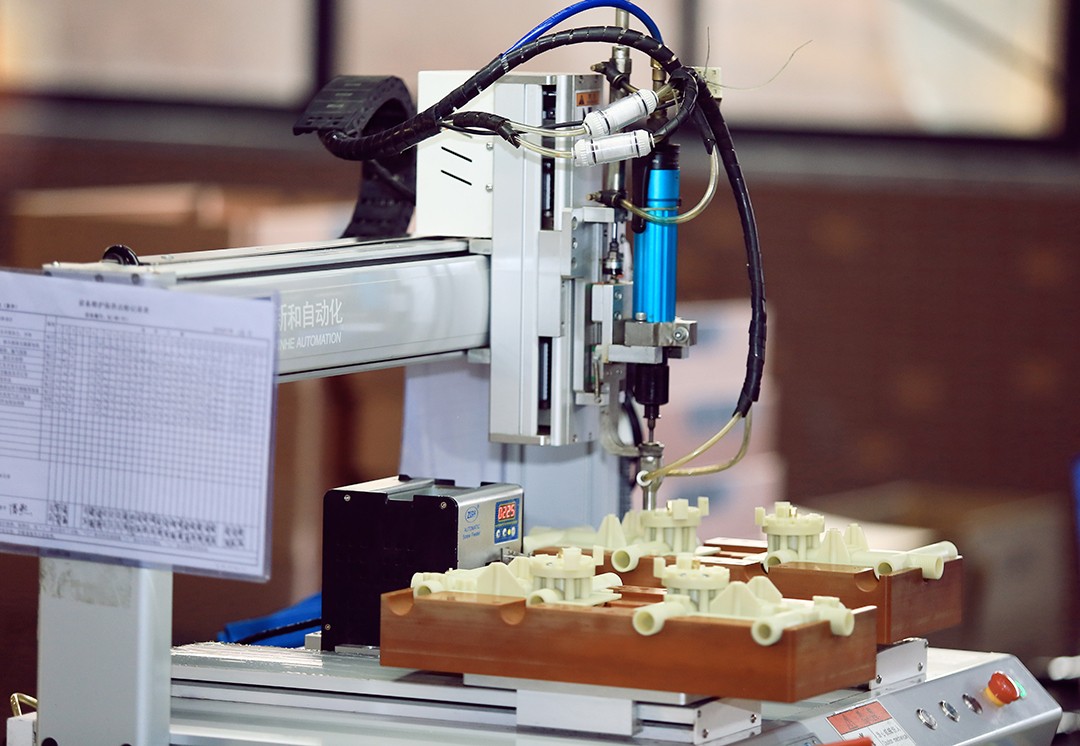

The company is equipped with advanced automated assembly lines, covering the complete process from parts processing to finished product assembly. The application of automated equipment has greatly improved production efficiency, reduced manual errors, and ensured product consistency and stability. For example, in the production of core components of electric water heaters (such as heating tubes and inner tanks), automated equipment can achieve high-precision processing to meet the strict requirements of the product for sealing and pressure resistance.

At the same time. MOKER introduced an intelligent detection system to monitor the quality of the product throughout the entire process. In the production of electric water heaters, the electrical performance and safety performance of the product (such as leakage protection and anti-dry burning function) are tested in real time through automated testing equipment to ensure that each product meets national standards and corporate internal control requirements.